The CMR Group production plants are able to guarantee the entire production cycle, thanks to modern machinery and advanced technologies, thus managing all the main mechanical processes: toothing, turning and grinding. All the necessary heat treatments are also available, and according to the specific requests of the Customers, at the end of the production processes, all the main surface treatments can also be performed.

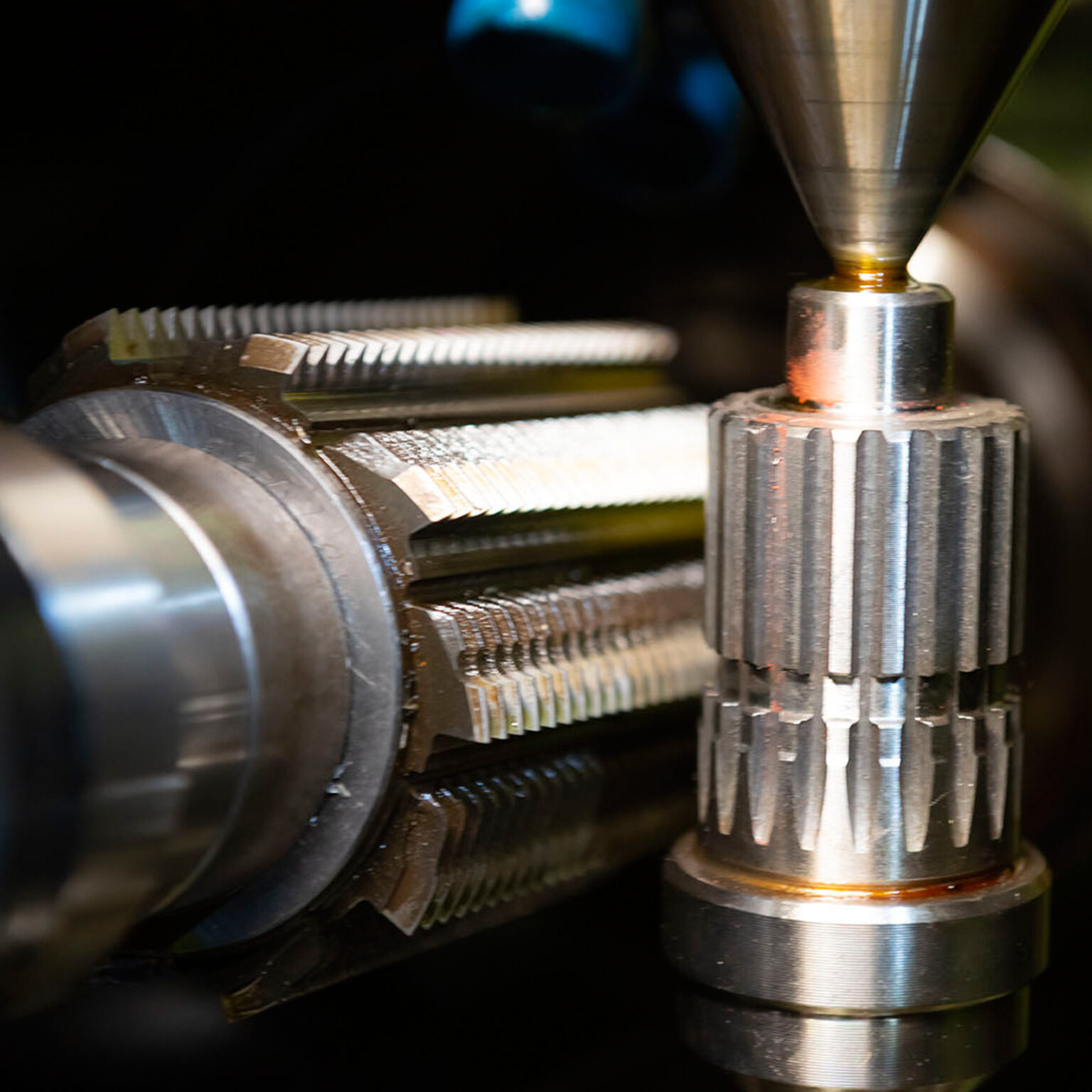

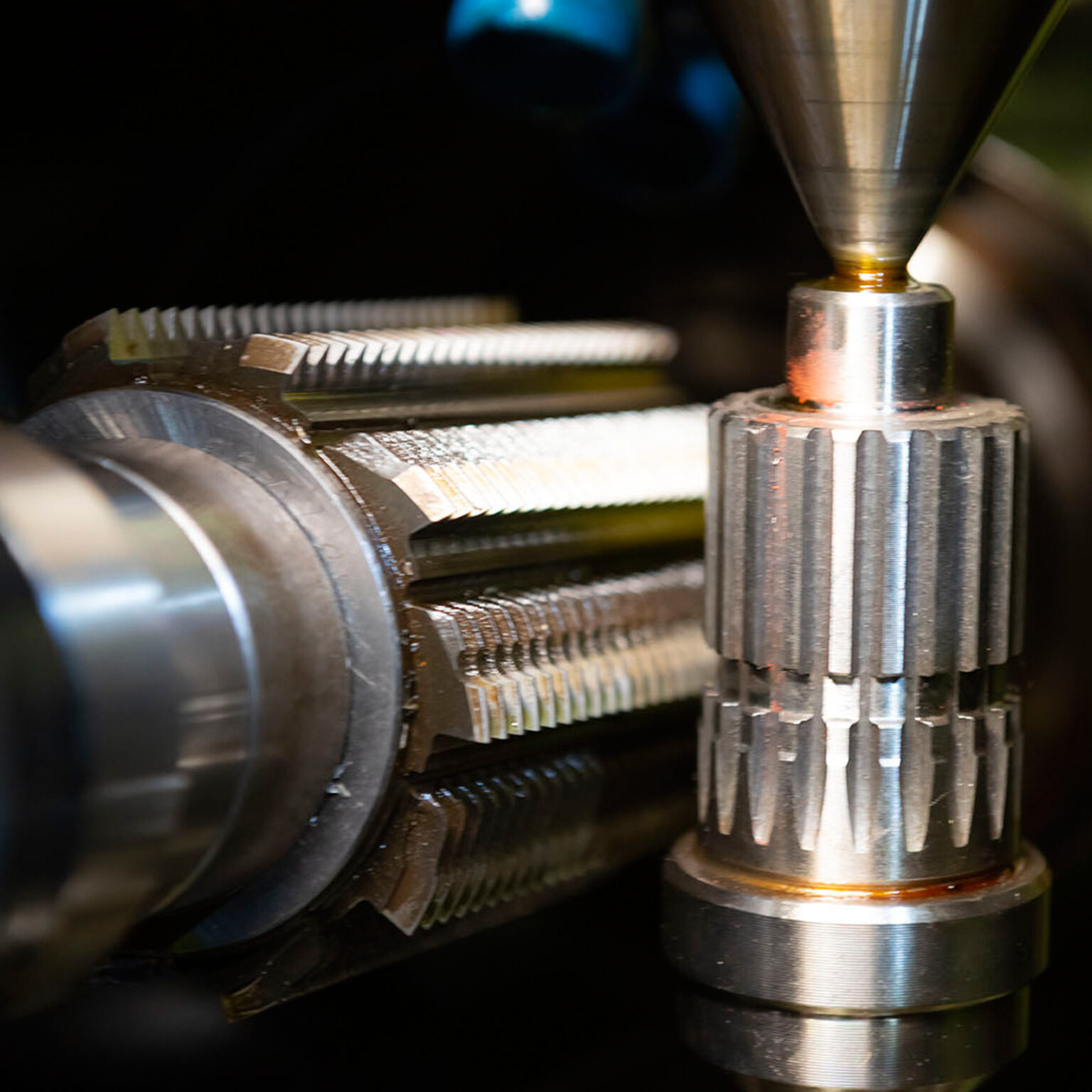

CMR Group has been manufacturing gears and transmission components of various types for more than thirty years. The in-house machinery department includes 75 gear cutters, both the conventional and numerical control types, tooth grinders, Modul, Gleason and Fellow shaving machines, while the experience acquired by highly qualified personnel ensures compliance with Customer requirements.

CMR Group produces modulus 0.5 mm to modulus 12 mm spur wheel, screw wheel and straight spur gears, straight bevel gear pairs and Gleason spiral tooth gears, worm screws, ring gears for worm screws, pinion, ring gear and chain systems with hobs up to 3’’ and diameters up to 2,000 mm plus splined shafts up to 4,000 mm in length according to drawings provided by the Customers.

CMR Group supplies finished products, inclusive of: material, processing, heat treatments and grinding. Each step in the parts production process includes stringent quality controls, product traceability procedures and continuous improvement of the internal methodologies and work flows. CMR Group subjects the incoming steel to inspections and verifications before manufacturing transmission components such as bevel gear pairs, racks, pinions, pulleys and gear wheels.

The company expanded its product range to an even greater extent by including bevel gear pairs produced by the electrical extrusion method, which provide a better performance than the standard type. CMR Group can provide certificates of conformity per production lot, subject to prior agreement with the Customer.

Fill out the contact form and send us your drawings or request a consultation from our Technical Department